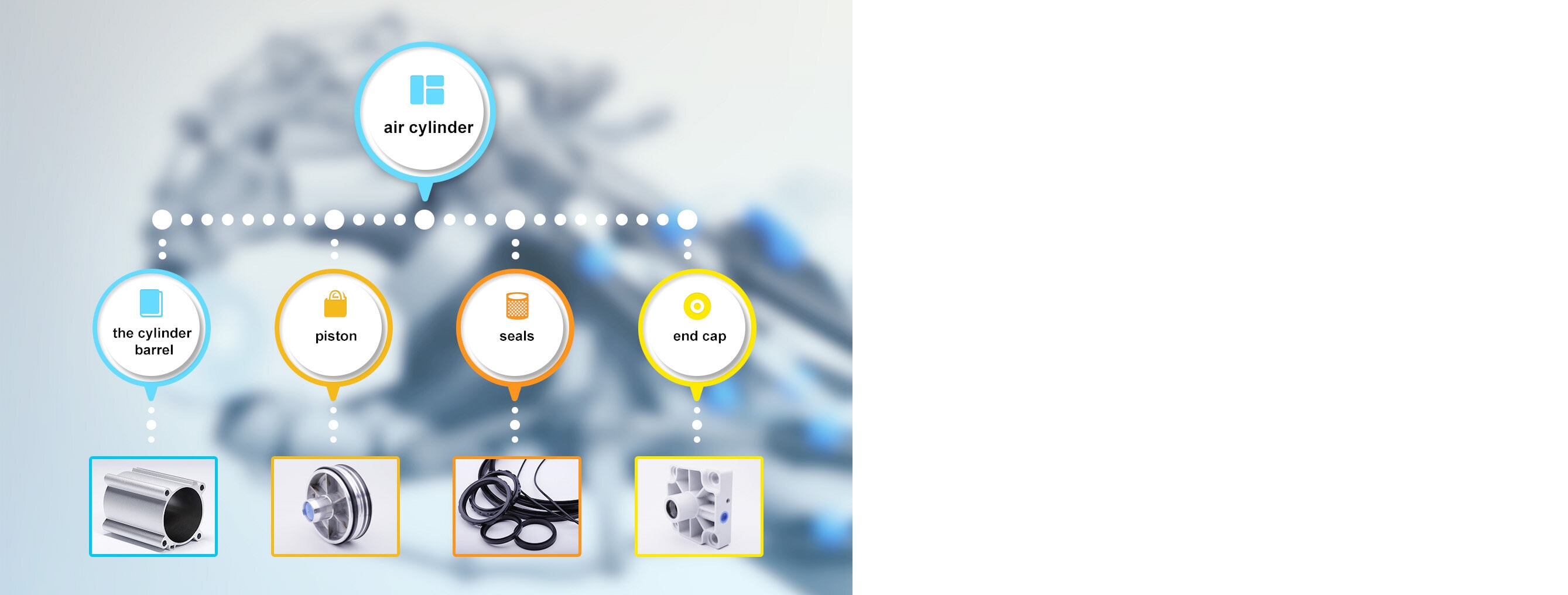

[Procedures] Article 228 The mine prevention and control of ground pressure (hereinafter referred to as anti-shock) shall comply with the following provisions: (1) Establish specialized institutions and personnel. (2) Adhere to the principle of "zone first, partial follow-up". (3) The medium and long-term anti-shock plan and the annual anti-shock plan must be prepared, and the special measures for anti-shock must be included in the work procedures for the mining face. (D) In coal mining rock burst layer, it must take the risk of impact prediction, monitoring and early warning, prevention treatment, comprehensive prevention and control measures to effect inspection, security and so on. (5) A training system for anti-shock must be established. [Implementation] (1) The impact pressure mine should set up a special anti-shock pressure (hereinafter referred to as anti-shock) mechanism, which is responsible for the prevention and control of the impact pressure, and is equipped with full-time anti-shock technicians and full-time construction teams. The impact pressure mine should improve various anti-shock management systems, clarify the responsibility system for managers at all levels, and carry out anti-shock work. (2) Regional advance refers to avoiding or reducing the stress concentration in the mining area from the aspects of mining layout and mining design, and preventing the occurrence of impact ground pressure. Before the mining operation, the risk assessment of the mining area, the division of the dangerous area, the design of the anti-shock, the development of the impact risk monitoring and treatment plan, and the regional monitoring and early warning shall be carried out. Partial follow-up is to optimize the adjustment of the ground pressure monitoring and prevention technology system according to the dynamic information such as monitoring information, impact pressure control effect and newly exposed geological conditions during the mining operation. (3) The mid- and long-term anti-shock planning of the impact ground pressure mine shall conduct impact risk assessment on the mining area, divide the impact danger area, and clarify the technical measures for prevention and control of impact ground pressure. The annual anti-shock plan for the impact ground pressure mine shall determine the dangerous area of ​​impact ground pressure within the annual mining range and formulate special measures for prevention and control. Special measures for anti-shocking should include evaluation and regional division of impact risk in the operation area, geological structure description and concise chart, mining location (including upper and lower layers) and its impact range map, excavation and recovery methods and processes, roadway and coal mining Support of working face, blasting operation system, prevention and control measures of impact ground pressure, emergency measures and disaster avoidance routes when impacting earth pressure disasters occur. (4) Prevention and control include regional prevention and management and partial relief measures. Regional prevention and control includes mining protective layers, optimizing production layout, rationally adjusting mining sequence, determining reasonable mining methods, reducing stress concentration, and adopting pressure relief measures in advance. Partial solutions for disaster relief include coal seam water injection, borehole pressure relief, blasting pressure relief, and hydraulic fracturing. The effect test is an evaluation of the effectiveness of the anti-danger effect in the impact area. The effect test methods include ground stress, microseismic, electromagnetic radiation, and drill cutting method. Safety protection refers to measures taken to avoid personal injury and equipment damage caused by impact pressure, including system improvement, personal protection, equipment fixing, and strengthening support. The basic components of a pneumatic cylinder include a cylinder body, a piston with a piston rod, seals, and an air supply. When compressed air is supplied to the pneumatic cylinder, it pushes the piston, causing the piston rod to move.Pneumatic Cylinder Barrel. Advantage of pneumatic cylinder Pneumatic Cylinder,Air Cylinder,Pneumatic Air Cylinder,Aluminum Pneumatic Cylinder Foshan Weiyingjia Technology Co., Ltd , https://www.wyspneumatic.com

Compared to other types of cylinders or power sources, pneumatic cylinders have the advantages of being cost-effective, easy to operate, and requiring minimal maintenance.Pneumatic Cylinder.

Principle of pneumatic cylinder

The working principle of a pneumatic cylinder is that compressed air enters the cylinder body, pushing the piston to produce mechanical motion or force. Its efficiency and effectiveness can be evaluated by calculating the relationship between the work and energy of the pneumatic cylinder, which is governed by the laws of thermodynamics.

A key principle of pneumatic cylinders is the relationship between pressure and motion. The force produced by the cylinder body is proportional to the air pressure supplied to it. This means that increasing the air pressure will cause the pneumatic cylinder to produce a greater force.

Categories

Pneumatic cylinders can be divided into single-acting cylinders or spring return cylinders and double-acting cylinders. Commonly used cylinders include DNC and SI series ISO 6431 standard cylinders, SC standard cylinders, and stainless steel miniature cylinders.

Application

Pneumatic cylinders are widely used in automation and control systems to compress and release gas or liquid to achieve the conversion of force and motion. They are used in manufacturing for assembly lines, in construction for heavy machinery, and in the automotive industry for braking systems, among other applications.

Cylinders play a crucial role in modern industrial and mechanical fields. If you want to learn more about cylinders and their benefits in applications, please contact us. We offer a range of articles, videos, and other resources on cylinders to help you better understand their working principles and application scenarios. Whether you are an engineer, technician, or ordinary consumer, you can benefit from this information.

We believe that by gaining a deeper understanding of cylinders, you will be able to better understand the technology and applications in modern industrial and mechanical fields.

Mine control impact rock pressure requirements

Mine control impact rock pressure requirements

A pneumatic cylinder is a mechanical device that uses compressed air to produce linear motion. It is commonly used in manufacturing, automotive, and construction industries to power a variety of machinery and tools.Air Cylinder Barrel.